GAS Deck Oven Three Tray Series

SLG-3009

Made In Taiwan

The Modular Gas Deck Oven is a fully automatic temperature-control & ignition baking solution. Equipped with the CE approval control unit, the oven provides superior features of uniform heat distribution, energy saving competence, and multiple safety mechanisms. Enhanced by its sleek appearance, this oven is not only a truly green oven, but also a fashion device to enjoy pleasantness of baking.

Features

1. Energy Saving Oven

The regulated gas mixed with injected air generates blue flames that make the oven to reach setup temperature in the short time. After reaching the desired temperature, the burners do not have to work all the time and gas is consumed only several seconds to offset heating loss. Furthermore, because the oven is installed with compact low-thermal-conductivity insulation and precise digital temperature controller, heat retention of the oven is excellent and over-heating is greatly eliminated. These distinguishing features greatly reduce unnecessary energy wasting, saving money for the owner.

2. Multiple Safety Mechanisms in Compliance with CE Standards

Fault-Component Self-Detection.

The central control unit will detect its components before ignition. If a component is damaged or malfunction, the unit will stop working and notify the operator via the safety alarm.

3. Flame Sensor Safety Device

The control unit is capable of detecting whether flames are normally ignited, there is incompletely combustion, and input supply is out of gas. After 6 second feedback detection, the unit will stop all controlling and notify the operator via the safety alarm.

4. False-Stop-Heating Safety Detection

If the temperature controller turns off the heating process, but the burner is still firing because of possible gas valve malfunction or gas piping leakage. The control unit is able to detect this situation and notify the operator by the safety alarm.

5. High-Rating Parts and Enhanced Control Unit Protection

The central control unit is composed of selective electronic components that require higher rating and can withstand harsher environment. The components are fully covered and sealed with protection glue and the whole controller board is further guarded in the plastic enclosure. These designs prevent possible damages and ensure normal operations in the high-heat and humid environment.

6. Double Solenoid Valves Safety Guard and Durable Piping System

Each burner piping is all controlled by two gas-grade solenoid valves. By doing so, this will double strengthen its working life and safety. Furthermore, all internal or external piping is used and connected with metal fittings to prevent possible damages such as collision and animal gnawing.

7. Precise Temperature Control and Uniformity in Baking

Independent, operator controlled top & bottom gas burners and the thermodynamic-design chamber make an uniform heat distribution over the entire chamber while providing precise temperatures. The resulting thermal condition of the chamber uniformly transfers the heat to the products. Top and bottom digital thermostats control each set of burner, allowing operators to determine the ratio of top vs. bottom heat and offering infinite possibilities to adjust the oven for baking every conceivable product.

8. Heavy-Duty and High-Precision Gas Burner

The gas burner is made of the seamless stainless steel tube fabricated by five axes bridge type machining center. The high-grade material offers robust structure to prolong burner working life. Ultra-tight tolerance machining is capable of having every gas oven to generate quality and uniform flames.

9. Contemporary Signature Style

Broadly angle edges, large supervising windows, premium brushed stainless steel front, and powder-coated black door handles deliver modern and professional taste. An elegant graphic-wording panel, precise dial-control knobs, and symmetrical control units are designed to maximize functionality, visibility, and your ease of use.

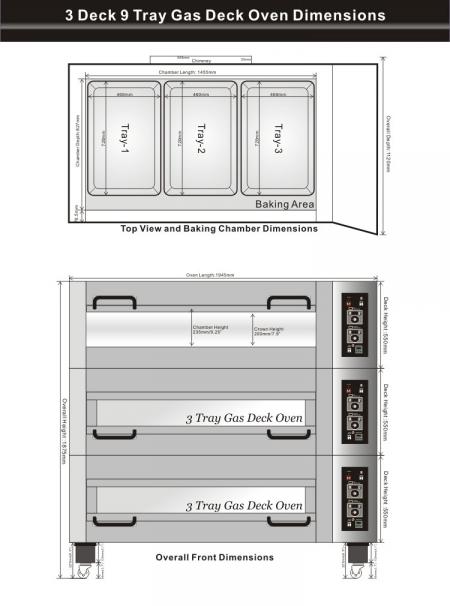

Specification

| Model | SLG-1003 | SLG-2006 | SLG-3009 | |

|---|---|---|---|---|

| Number of Deck | 1 | 2 | 3 | |

| Number of Tray Per Deck | 40 x 60 cm | 4 | ||

| 46 x 72 cm | 3 | |||

| 46 x 76 cm | 3 | |||

| Number of Tray Per Oven | 40 x 60 cm | 4 | 8 | 12 |

| 46 x 72 cm | 3 | 6 | 9 | |

| 46 x 76 cm | 3 | 6 | 9 | |

| Size of Baking Chamber | Depth | 827 mm (32.6”) | ||

| Length | 1455 mm (57.3”) | |||

| Height | 200 mm (7.9”) | |||

| Size of Oven | Depth | 1120 mm (44.1”) | ||

| Length | 1945 mm (76.6”) | |||

| Height | 550 mm (21.7”) | 1725 mm (67.9”) | 1875 mm (73.8”) | |

| Size of Crated Oven | Depth | 1220 mm (48.1”) | ||

| Length | 2045 mm (80.5”) | |||

| Height | 750 mm (29.5”) | 1925 mm (75.8”) | 2075 mm (81.7”) | |

| Approx. Net Weight | 270 kg (595 lbs) | 570 kg (1256 lbs) | 850 kg (1874 lbs) | |

| Approx. Gross Weight | 320 kg (705 lbs) | 640 kg (1410 lbs) | 960 kg (2116 lbs) | |

| Approx. Gas Consumption (kg/hr) | 0.375 | 0.75 | 1.125 | |

| Voltage | 220V/110V 50/60HZ Single Phase | |||

| Approx. Power Consumption | 185W | 370W | 555W | |

| Maximum Operating Temperature | 400°C / 752°F | |||

Options & Accessories

Steam Generator

The steam generator absorbs recycle upward heat and generates strong steam while water is injected into the bottom cavity of the deck. Generated steam evenly disperse the entire baking chamber from air side tunnels. The steam generator does not consume any extra electric power and ensures rapid recovery.Stone Hearth

The stone is 2cm (0.8") thick and high-retention refractory material. These make whole heath can absorb much more heat and produce both a crispier bottom crust and more golden brown color for foods.Best Sale

Hot Products

Spiral Mixer

We have brought extensive knowledge to its high quality mixers in the past 30 years.

Read More